Cookie Consent

We make use of cookies, content and tools of third parties on this website. Some of them are nessecarry for the functionality of this site, while others help us improve our offer to be more user friendly.

content

Technology matters

Thinking ecologically and acting economically - DESMA is on its way to more sustainability

DESMA Schuhmaschinen GmbH in Achim in the north of Germany already launched a large number of measures years ago to mark the start of a new era of sustainability.

- sustainability

- recycling

- resource-saving

- direct soling

Content has been blocked due to privacy choices

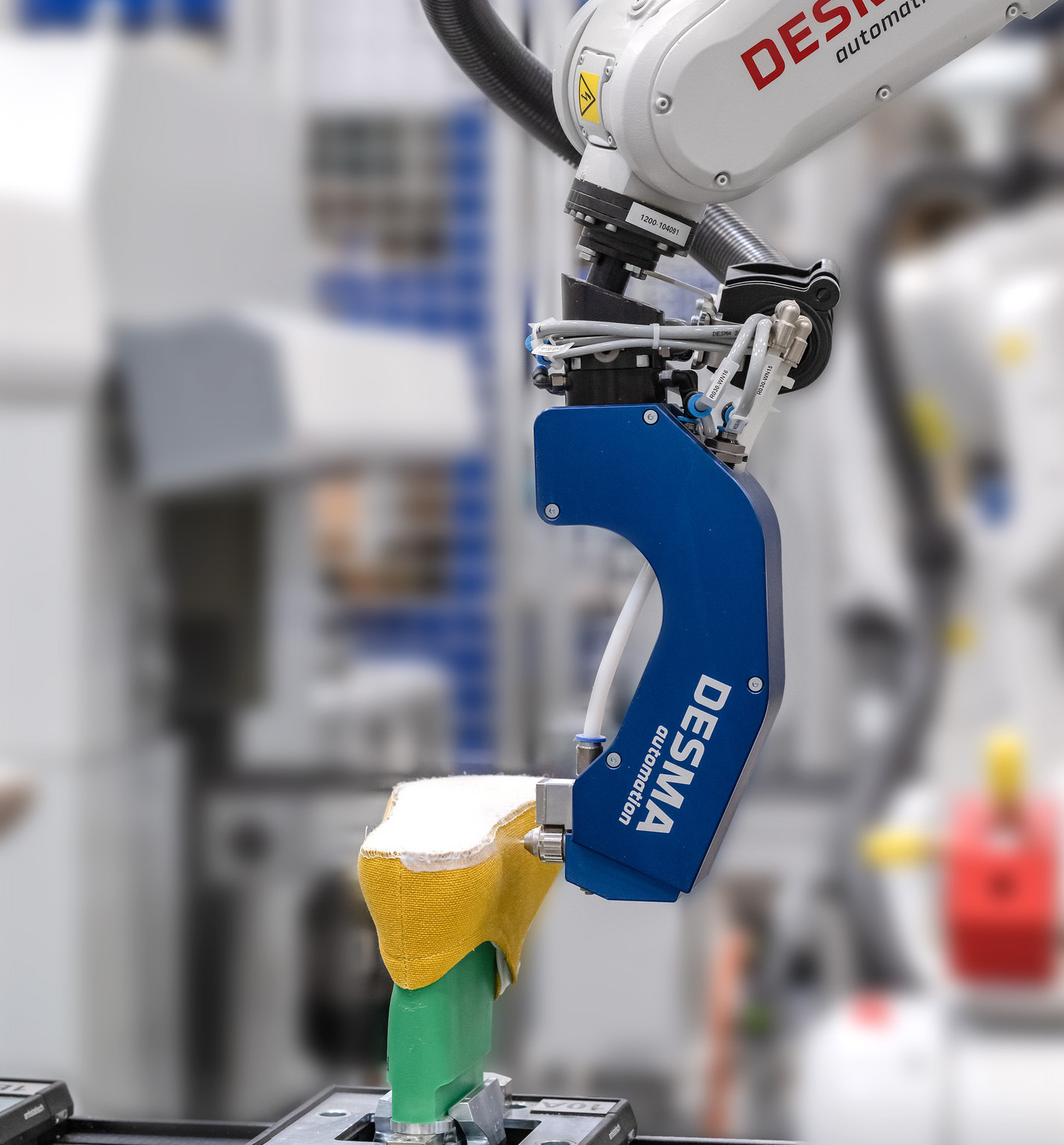

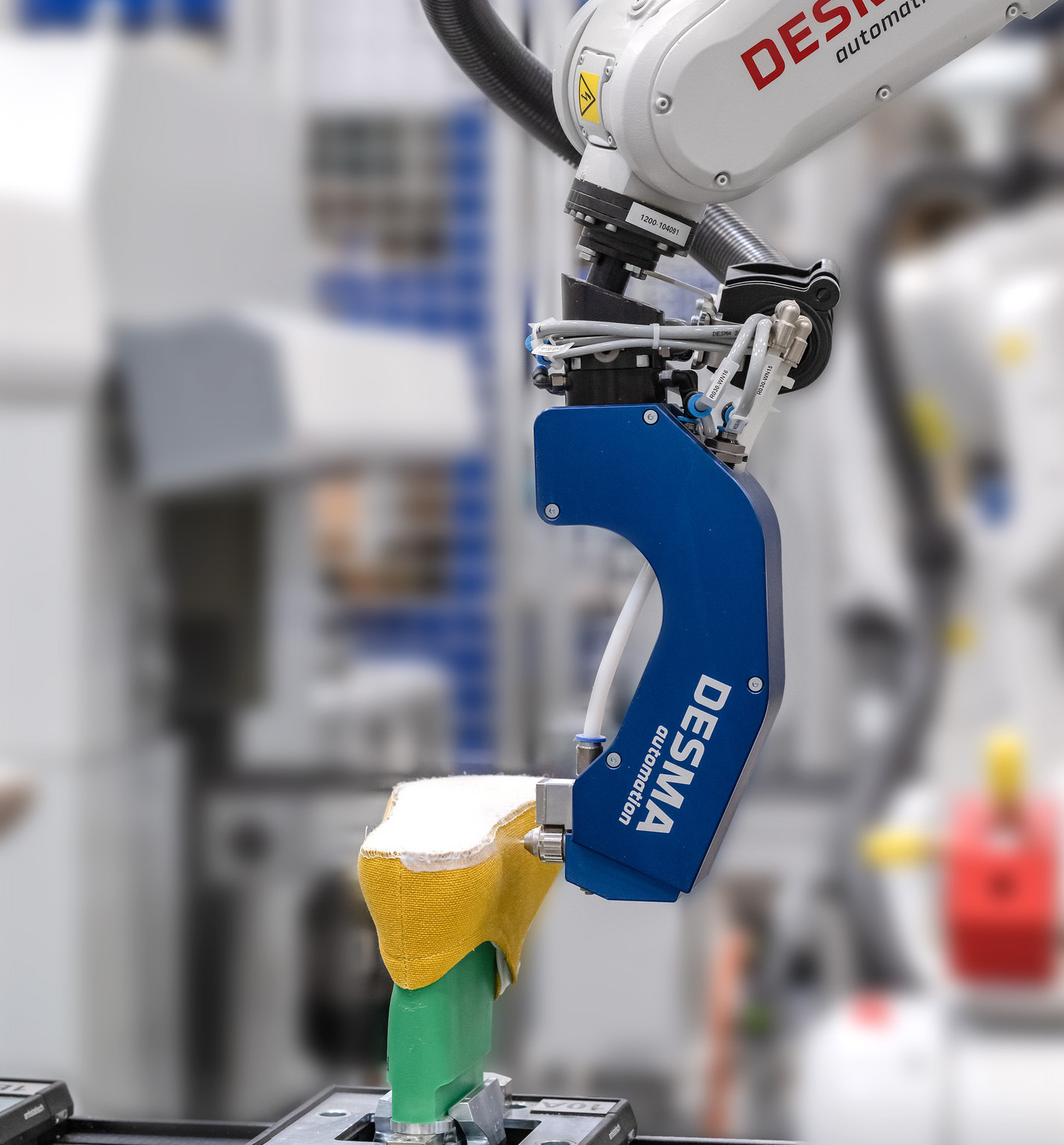

DESMA amir®c - precise, reliable, and flexible cementing of upper and sole

Advanced automated unit for priming and cementing uppers and soles, managing the entire process up to pressing.

Traditional cementing manufacturing heavily relies on manual labour. With DESMA automation solutions, a significant portion of manual work can be replaced, enabling efficient production of high-quality shoes.

- cementing

- robotics

- automation

- highest quality

- efficiency

Robotergestützte Lösungen für das Verkleben von Schaft und Sohle mit amir®c

Robotik- und Automationslösungen der DESMA Schuhmaschinen GmbH unterstützen die Schuhindustrie durch automatisierte Arbeitsabläufe mit erhöhter Produktqualität, Effizienz, Flexibilität und Nachhaltigkeit.

- automation

- cementing

- efficiency

- flexibility

- sustainability

robot-aided solutions for cementing upper and sole with amir®c

Robotic and automation solutions by DESMA Schuhmaschinen GmbH help the footwear industry automate production processes and raise product quality, efficiency, flexibility and sustainability.

- automation

- cementing

- efficiency

- flexibility

- sustainability

Content has been blocked due to privacy choices

DESMA House Fair 2022 - Technology matters

On the 26-27th September, the global footwear industry met in Achim to talk about the latest technologies and trends. It was great to see everyone again after a long break and we thank everyone for your participation!

- House Fair

- partnering

- DESMA-ology

- conference talk

- innovation

Content has been blocked due to privacy choices

DESMA Schuhmaschinen - Pioneering the World of Footwear Creation

Pioneering the World of Footwear Creation - this is our new vision for the upcoming years. In this video, our Managing Directors Christian Decker and Klaus Freese explain the new vision and our new mission: Partnering for major Steps forward!

- House Fair

- innovation

- partnering

Content has been blocked due to privacy choices

Multilayer Performance - Footwear with a Purpose

In this webinar we have been deep-diving into the advanced possibilities of the DESMA technology for Direct Injection Process (DIP): Aiming at highest and consistent product quality as well as the realization of design und functional requirements multilayered footwear is upgrading the performance characteristics of your products. Whether retrofitted to your existing machines or taken into consideration for new investments, DESwing and / or Center Wedge enable new product features!

- design4manufacturing

- sustainability

- direct soling

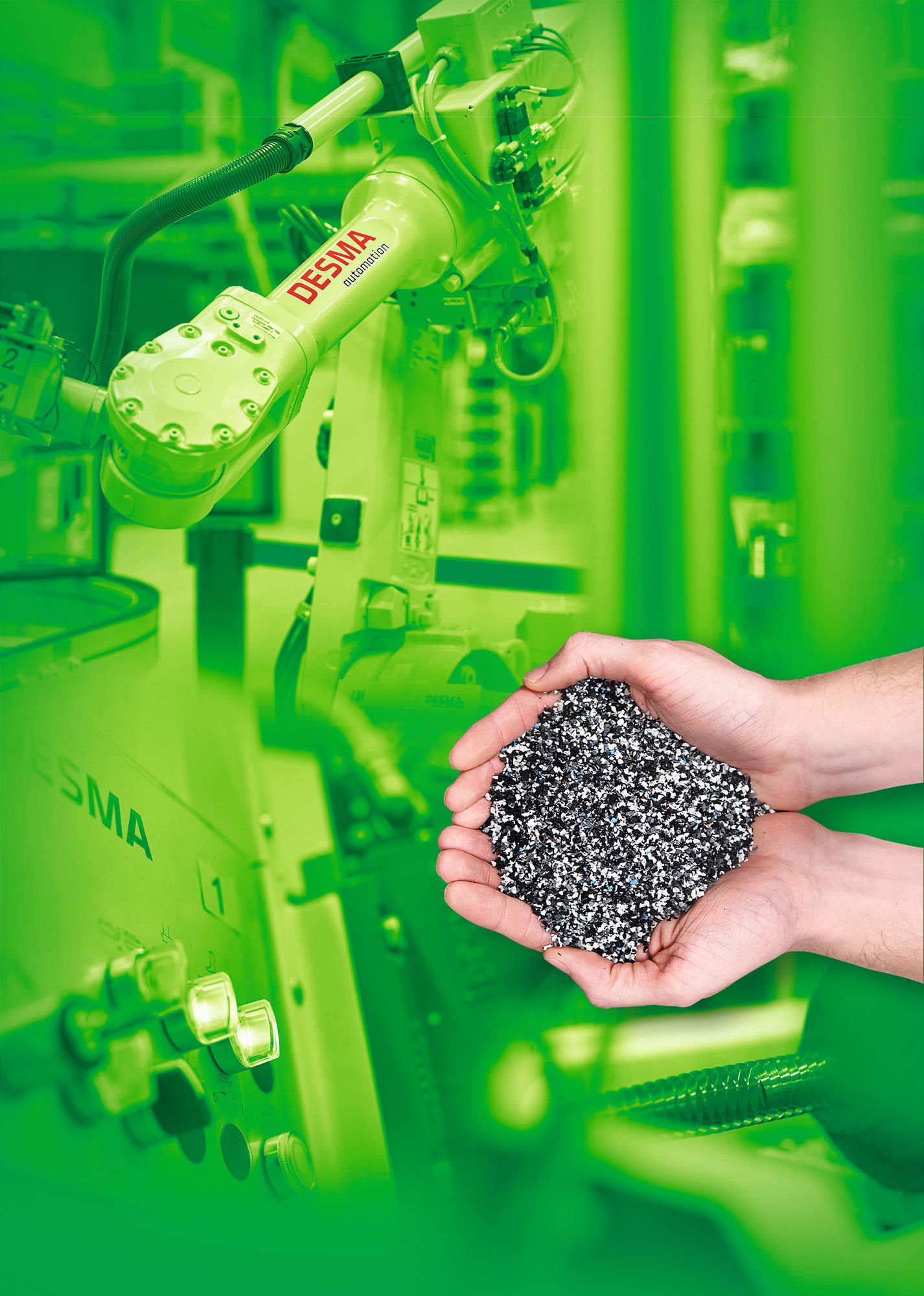

Reduce – recycle – rethink: ideas for more sustainable footwear production

The issue of sustainability increasingly impacts the footwear industry. Innovative technology can be a game-changer for minimizing the carbon footprint of footwear production.

- recycling

- sustainability

- resource-saving

- automation

Content has been blocked due to privacy choices

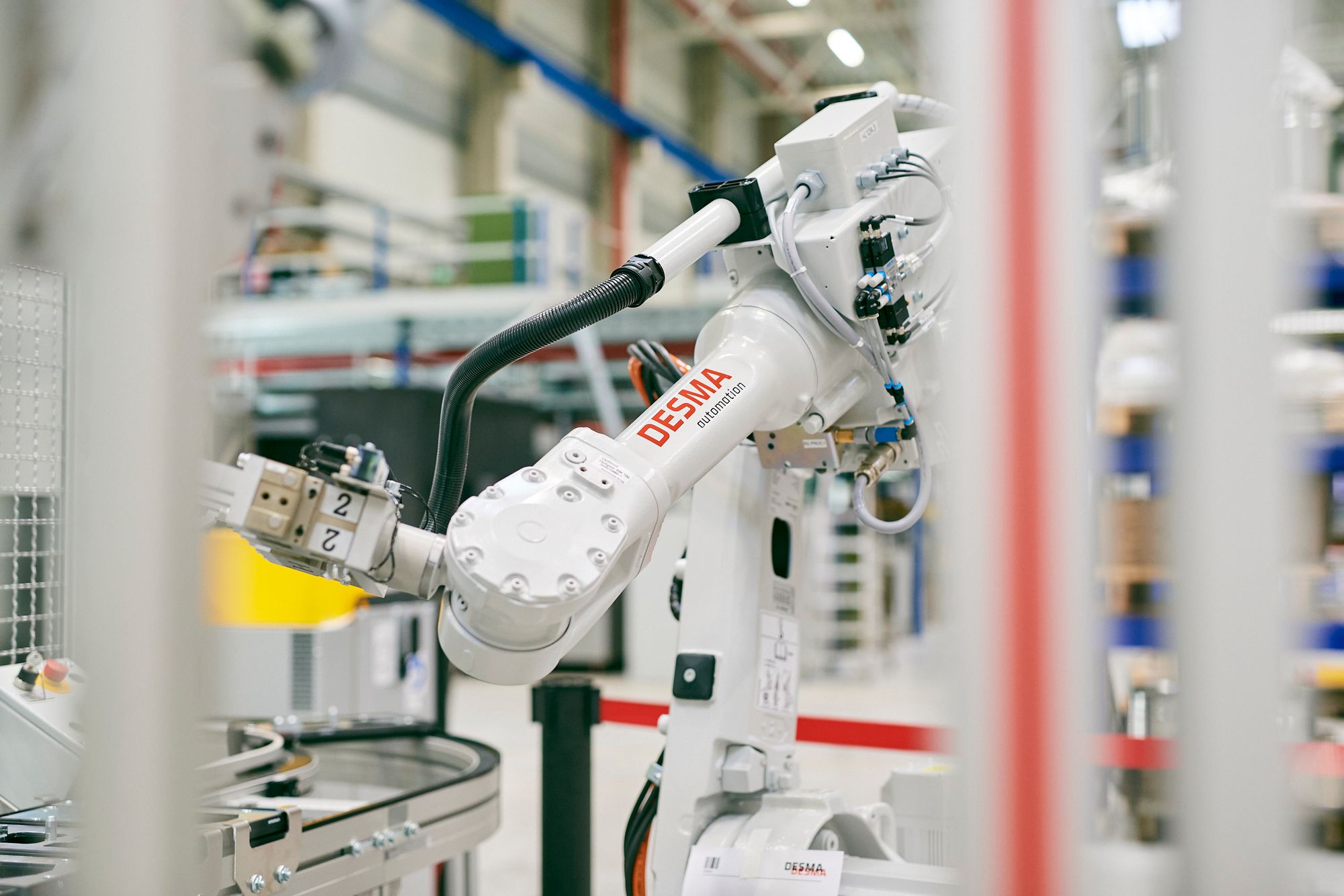

Automation at its best

The automation of footwear production is progressing at an increasingly fast pace. DESMA solutions allow you to design your production processes so that you can manufacture shoes in top quality and with maximum efficiency. Our solutions deliver reliable and reproducible processes to make your operations more cost effective and enable you to respond flexibly and sustainably to all future requirements.

- automation

- robotics

- highest quality

- efficiency

Footwear production of the future: smart, digital and close to the consumer

Innovative technologies, such as automation, the use of robots, digitisation and order-driven production processes, can help ease the challenges faced by the international footwear industry.

- speed2market

- design4manufacturing

login for access!

Future Footwear Supply Chains - Turning the global challenges into opportunities

Global footwear producers are now faced with the need to completely rethink their risk management. This includes options such as supply chain optimisation and diversification, as well as the use of innovative materials, customised product features and greater design variety. Companies that want to be successful in the future will have to deal with important milestones such as new technologies, shorter innovation cycles, automated, environmentally friendly and resource-saving production facilities, the use of robots and the further development of order-driven production processes.

premium- speed2market

- design4manufacturing

- sustainability

login for access!

DIRECT INJECTION PROCESS (DIP) MEETS PARTICLE DOSING

The addition of granulated production waste, recyclates or other sustainable fillers reduces the use of polyol and isocyanate in direct soling processes. This is the next answer devised by DESMA in response to the need for sustainability in direct soling. The particle dosing unit can be retrofitted and, together with modification of the machine and visualisation software, allows the use of fillers such as production waste or other solids. This significantly improves the sustainability footprint of direct soling.

premium- resource-saving

- sustainability

- recycling

Sensorüberwachter Zustand von ausfallkritischen Komponenten einer Einspritzeinheit

Neueste Erkentnisse aus dem BMBF-Verbundvorhaben „LongLife“ einem Teil der Fördermaßnahme „Ressourceneffiziente Kreislaufwirtschaft – Innovative Produktkreisläufe“ (ReziProK).

- language: german

- process reliability

- sustainability

- big data

- maintenance

Content has been blocked due to privacy choices

Sustainability @ DESMA

But what makes us sustainable? There’s still a lot to be done. But we have taken the first steps. Production facilities that are advanced and sustainable. Workspaces that fit people. Designing new products is about more than just saving energy. Automated production today – for a sustainable tomorrow. We take responsibility for the way we are using Earth’s resources. And for the path we are travelling together.

- sustainability

- future

login for access!

Multi Section Injection (MSI): advancing DIP to the next level

With Multi Section Injection (MSI) technology, DESMA has once again significantly advanced Direct Injection Process in the areas of design diversity, sole properties and process reliability. In different areas of the sole, different properties, e.g. degrees of hardness, and colour combinations can be achieved with each material injection, and all this individually controlled, shot by shot.

This webinar is aimed at interested participants who already have a basic knowledge of DIP.

premium- design diversity

- different sole properties

- process reliability

Content has been blocked due to privacy choices

Direct Injection process (DIP) is DESMAs DNA

Direct Injection Process is the core technology of economical and at the same time environmentally friendly and resource-saving shoe production. The sole material is injected directly into the mould and penetrating the shoe upper, ensuring perfect adhesion between the upper and the sole. The sole material uniquely encloses the upper and thus there are almost no limits to creativity in sole design, combinations and effects.

The webinar introduces the basics of the Direct Injection Process and does not require any special knowledge.

- resource-saving

- highest quality

- lean and clean

- sustainability

login for access!

Rapidly Converting Your Ideas Into Products

The DESMA Customer Service Center (CSC) is living up to its name: from field service and smart remote service to spare parts supply and even staff training. The CSC offers a unique combination of key production factors: equipment, expertise, material and design. These form the basis for excellent direct soling and automated footwear production – and consequently for your success.

In this webinar we are going to introduce to you the philosophy and the services our DESMA Customer Service Center (CSC) is offering. Doing so, we like to boost your confidence in DESMA being your partner while using your footwear soling and manufacturing solutions to its fullest.

premium- webinar

- Customer Service Center

login for access!

See behind the curtain of your shoe production

We feel that data is the new gold and that a profound data analysis is key to improve both the efficiency and the sustainability of your shoe production.

premium- webinar

- big data

- data analytics

- automation

Content has been blocked due to privacy choices

Highly efficient shoe solution by DESMA & STOLL

KARL MAYER STOLL and DESMA are answering the increased demand for drastically reduced lead times by cooperating and establishing closed supply chain technology. This enables customers to faster create trends or to react to market requirements in the future.

- materials

- automation

- KARL MAYER STOLL

Footwear production through the ages

New materials and manufacturing processes define the course of international footwear production – Globalisation and digitisation provide opportunities for both service providers and manufacturers – Sustainability becomes increasingly important

- direct soling

- sustainability

- history

Sustainability becomes increasingly important

Content has been blocked due to privacy choices

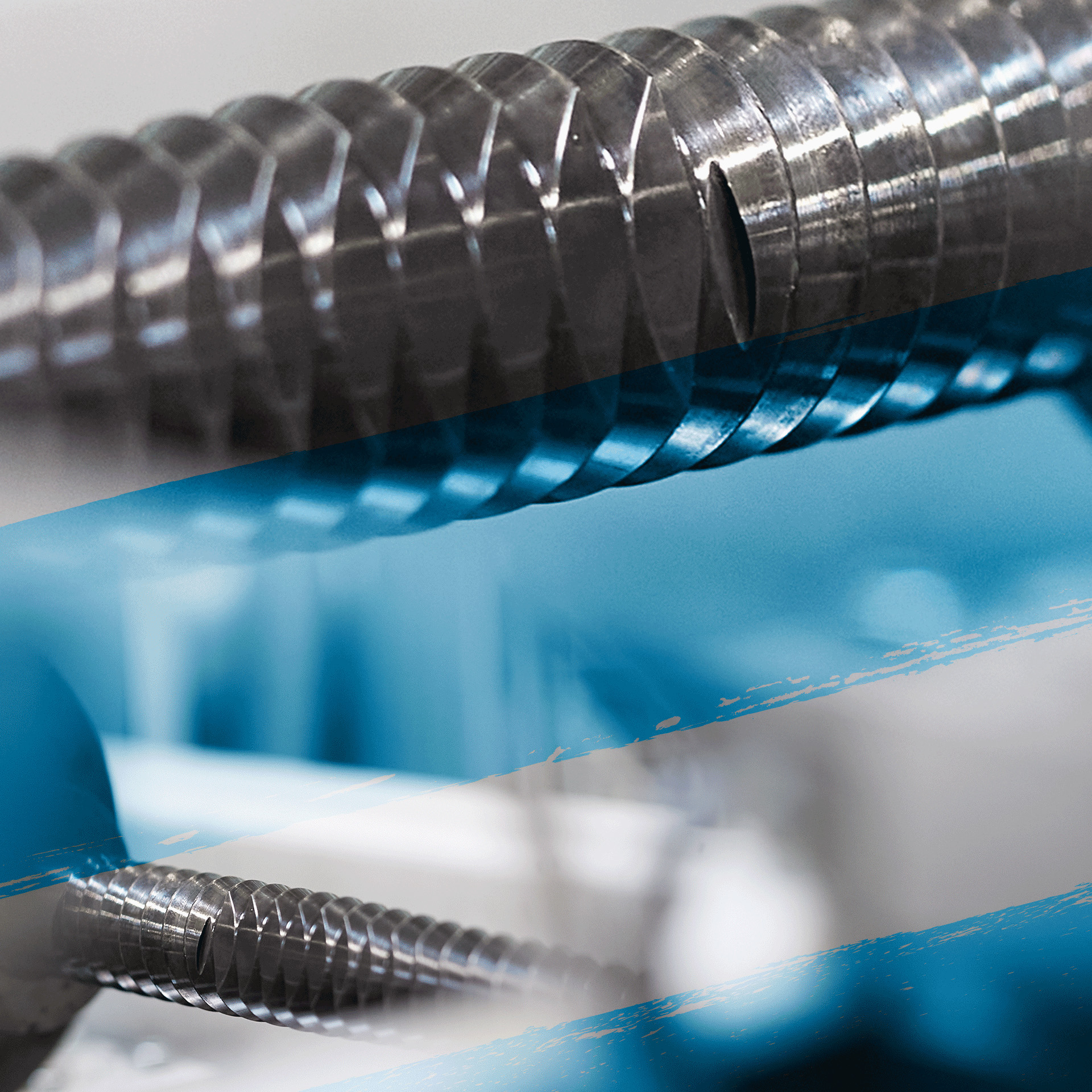

Upgraded Automation Solutions – Roughing NX

Automation and robots: paying their way

Do you want to achieve optimum adhesion of sole to upper in direct soling processes? How to prepare the upper in a precise and reproducible process? We would like to present these to you during this recorded webinar.

- webinar

- materials

- robotics

- adhesion

- soling

Robots Don’t Have to Self-isolate

Post-pandemic footwear production:

how robots, the Industrial Internet of Things (IIoT)

and order-driven production processes can make

the industry more crisis-resistant

- robotics

- covid19

- automation

The greatest challenge facing the footwear industry is to develop a robot which can insert shoelaces properly.

Content has been blocked due to privacy choices

2020's - decade of disruptive changes of the global footwear market

The CEO of DESMA, Christian Decker, presented this pitch about the footwear industry during the first session of the SAFETY FOOTWEAR REVOLUTION WEEK 2020. A fully digital and virtual conference that aims to be a milestone in the footwear Sector.

The present pandemic the World is living in, the controversial geopolitical tensions, and the increasing environmental challenges we’re facing, alongside unprecedented materials, artificial intelligence, and workforce evolution, create a moment of enormous uncertainty and opportunities for the Footwear Manufacturing sector.

- automation

- robotics

- covid19

- conference talk

- sustainability